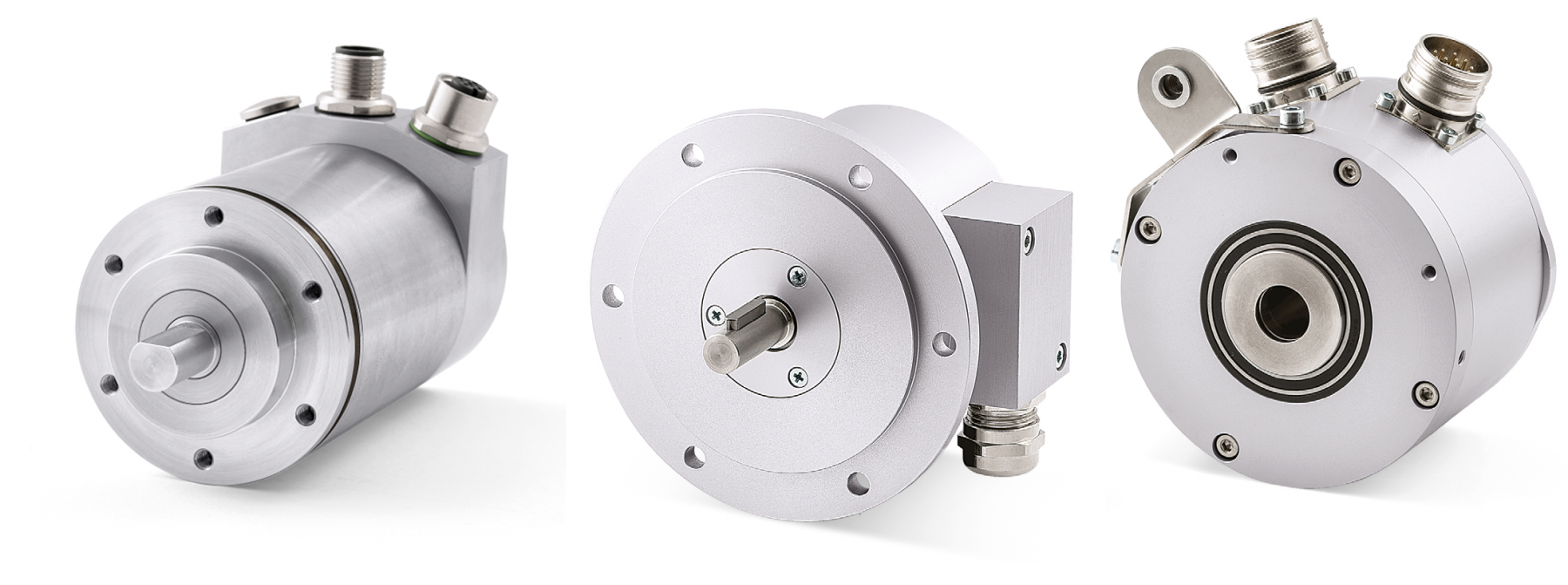

Heavy-Duty and ATEX encoders: rugged to deal with the roughest conditions

Harsh and hazardous environments require tough encoders with reliable and solid design, rugged mechanics, high reliability components, immunity to interferences, appropriate surface treatments and coatings, hermetically sealed housing. The comprehensive range of heavy-duty and ATEX encoders from Lika Electronic is designed to cope with several and different extreme conditions such as in oil and gas facilities, off-shore and marine installations, on/off shore wind turbines, shipbuilding industry, heavy vehicles and construction machinery, mining industry, iron and steel mills, chemical plants, food industry, petrol refineries and laboratories, painting machines, fertilizer plants.

Heavy-duty encodersEvery extreme application needs special requirements to be met. For each and all Lika has the right encoder to pick from. Heavy-duty encoders can mount rugged enclosures made of aluminium or stainless steel with oversized frame walls and ball bearings (see C101 and AM58K encoders). Bearings can be capable of handling the most severe applications affected by heavy mechanical stresses, shocks, vibrations, and high axial and radial shaft loads. For such very critical applications bearingless modular encoders (see SMLAX encoder) offer the greatest protection thanks to the contactless operation with magnetic sensing and encapsulated circuitry. Special surface treatments and sealings can be added to ensure safe protection against salt water corrosion, cleaning agents, and chemical contaminants. The bearings and shaft can be electrically insulated to provide insensitivity to eddy currents. The range of heavy-duty encoders includes both optoelectronic and magnetic measuring technologies |

High-quality and selected electronics is fully overmoulded and resin-coated and can withstand large temperature fluctuations up to -40°C +100°C (-40°F +212°F). Safe and dependable signal transmission at high counting frequency is granted even over long distances greater than 300 m (984.3 ft) thanks to high-performance Power Push-Pull and Power Line Driver output circuits: they considerably reduce quality degradation or loss of signals on long cable runs for maximum reliability without the need for repeaters and amplifiers (see C100 encoder). In addition Lika provides optical fiber modules for robust, safe, and reliable transmission of incremental and SSI absolute encoder signals over very long distances up to 3,000m (3,281 yd), see IF60 series modules. To improve reliability and further increase safety of data exchange the range includes redundant encoders with separate sensors and/or independent galvanically separated double output circuits, power supply and wiring; and dual encoders, i.e. two independent encoders in the single package with separate and reversible terminal block connections (see I116 encoder). |

ATEX encoders

ATEX encoders are designed to cover a wide variety of cri-tical applications in hazardous areas. XC77 and XAC77 series ATEX certified incremental and absolute encoders are “high protection” category 2 com-pliant encoders: they provide an airtight, explosion-proof and flameproof enclosure and high ignition protection le-vel against both gas and dust explosive atmospheres and are intended for use in Zones 1, 2, 21 and 22 and in the temperature class T6 (T85°C) |

SMLAX + MRx incremental and absolute modular enco-der is IECEx and ATEX certified for use in potentially explosive areas affected by combustible gases and marked as suitable for Zone 2, Gas group IIC, and Temperature class T4 (-10°C +85°C, +14°F +185°F). ATEX category is 3 G. XAC80, IX58, and CX58 series ATEX certified encoders are incremental and absolute encoders designed to provide “normal protection” in potentially explosive atmospheres (category 3) and are allowed to be used in Zones 2 and 22 and in the temperature class T5 (T100°C).

|

Share:

Recent articles

EX ZS 73 SR

EX ZS 73 SR Ex zone 1 and 21 Metal enclosure 2 contacts Cable Belt-alignment roller made of stainless steel Special version only f...

Read more...The new product from our partner SIKO GmbH

Draw-Wire Encoders SG31 robust design for rotary encoder mounting with 3000 mm measuring length Smart sensor family for mobile machi...

Read more...The new products from our partner Lika

ASB62 and CB62 Encoders for Feedback on Gearless and Servo Motors ASB62 absolute rotary encoder and CB62 incremental rotary encoder a...

Read more...